Panel Page

Firewall Forward

Interior Installation

3/16/99; 6.5 hrs; working with fiberglassing upper gear intersection

fairings; installed platenuts for emp fairing.

I am tired and totally disgusted after spending several hours in

fiberglass resin. This is the most despicable part of this project so far, far exceeding

proseal. There are no photos, because I was too sticky to even pick up the camera. Besides

that, I don't want to be reminded of fiberglass. Matter of fact, at this point I don't

even want to think. Good night.

3/17/99; 4.0 hrs; installed emp fairing; glued airscoop to cowl.

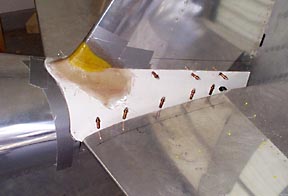

The fit of the emp fairing was pretty bad out of the box. However, after

the area at the root of the vert stab was cut away, the fit got better. Then, the whole

thing was reshaped with a heat gun. At that point, it fit quite nicely. I had to reglass

the area that had been removed earlier. Duct tape was applied to the stab to keep the

resin from sticking. The yellow stuff is Play-Doh that was used as a filler to build up

the shape of the stab.

I guess I am one of the lucky ones: I could actually use the emp fairing

that came with the kit!

Scoop was bonded to cowl with a combination of resin and mat. Once again,

quite a bit of time was spent with the heat gun getting the flanges to behave properly.

Lots of clecoes hold the flanges in place as the resin kicks. All the holes will be

covered by glass cloth and filler.

3/22/99; 6.75 hrs; fabricating aluminum gear intersection fairings.

I hate fiberglass!! I decided to try fabricating some aluminum fairings

before resorting to the fiberglass.

A paper pattern was cut out and taped into place. Considerable trimming

was necessary to get the proper profile.

Here is what the pattern ended up looking like.

Fairing is fastened together with a countersunk #8 screw and platenut.

Here is how the upper fairings are secured in place (1/27/00)

"Ears" were riveted to the inside of the fairings and safety

wire was attached to the ears and to a spring. The spring is attached to a hook fabricated

from stainless welding rod.

This is looking down at the gear leg. You can see the hook placed over the

gear leg brace. The wire is adjusted so the spring has moderate tension.

Hmmmmmmm....not bad! It only took two attempts to get to this point.

3/23/99; 4.0 hrs; completed lower gear fairings.

The bottom fairing is, well........ interesting. There are

several bends the sheet stock has to make. I used many pieces of poster board to make a

pattern. Matter of fact, I probably could have used it as a male mold for fiberglass

fairings. The pattern was cut apart just below the gear leg fairing and transferred to

aluminum.

I really didn't know if the aluminum would bend as necessary to form the

fairing. However, it did after much persuasion. This looks like it might actually work!

The fairing is fastened together with hinge material.

Now, to devise attachment hardware....

The two rear attachments are simply platenuts mounted on the wheelpant.

The forward attachments are 0.5" x 2.0" strips that are riveted to the inside of

the pant and carry a platenut on the outside.

The fairing has to split so it can be wrapped around the gear leg. A hinge

on the inside is used to fasten the fairing together.

As you can see by the pattern on the floor, the shape of the fairing is

complex; However, it will wrap as shown without any compound curves.

Here is the finished part. While not quite as detailed as a fiberglass

fairing, I can now build one in a couple of hours! The mounting is very rigid and the

fairing follows the contours of the wheelpant very nicely.

Not bad, eh? Rubber channel will be added to finish the intersection

between the two fairings.

Yes, making the aluminum fairings requires a lot of patience. However,

once they are finished......they are finished! I hate sanding fiberglass.

3/24/99; 2.75 hrs; More work on fairings; installed fire extinguisher; cut

and installed carpet padding.

Update 8/30/00; Now, after you have read all about the

metal fairings, click here to see what replaced them, and

resulted in more speed!

A platform was fabricated so the extinguisher will sit above the carpet

padding. It is located just forward of the fuel valve.

3/25/99; 2.0 hrs; working on air intake scoop.

After bonding the scoop to the cowl, lightweight filler was applied to the

joint. When cured, the filler and flange was sanded down smooth. Then a layer of glass

cloth was applied.

3/26/99; 1.5 hrs; made molds for nav lights.

The AeroFlash nav/strobe light assemblies need to be mounted on the

wingtip so they are visible from above the plane. I used floral foam from the composite

aircraft department of Walmart to craft a mold that will be fiberglassed. These items are

available from Van's in case you aren't as cheap as I am (However, I am not sure if they

fit the AeroFlash units or not).

3/27/99; 5.5 hrs; fiberglassed nav light mounts; working on air intake

scoop.

I scooped out most of the foam after the layup had cured.

3/31/99; 5.25 hrs; working on emp fairings; completed elevator trim

installation; completed gear fairings.

The plans call for pop rivets to attach the trim cable attachment nut to

the trim cover. This means it would be very difficult to remove the cover. I

opted to use a couple of platenuts instead.

4/3/99; 9.0 hrs; completed airseal installation on baffles; installed air

ducts in top cowl; fabricated and installed cowl hardware; modified canopy release.

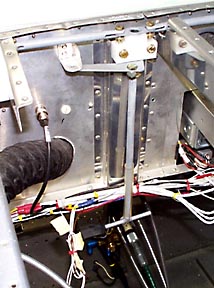

I decided to modify the canopy release so it could be reached easier. The

original tee handle was attached to the release bellcrank so I could reach it without

having to snake under the subpanel. The release is for maintenance purposes only since I

have no intention of jumping out of my plane...

Here are those odd little fiberglass parts that you couldn't figure out

where to install. This are supposed to smooth the airflow into the baffles. I bonded them

to the intake lip with resin and mat, put in some flush pop rivets, then bonded them tot

he top of the cowl in the same manner. I should have waited about bonding them to the top

until the attachment at the spinner were completed because they pulled the front of the

cowl out of shape. They have to be trimmed a good bit to clear the baffles. I never did

figure out how to completely seal around the inboard end of the things with the airseal

fabric.

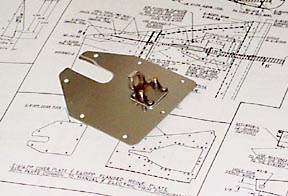

Here are the attachments at the front of the cowl. The plate on the

outside corner covers the slot where the hinge pin is installed and prevents the pin from

sliding out of the hinges.

I used three #8 flush screws and platenuts per side behind the spinner.

The platenuts are riveted to a plate that is in turn riveted to the cowl.

4/10/99; The shop has been cleaned out in preparation for wing attachment

and all that goes along with making this RV6 really look like an RV. Per careful and

deliberate guesstimation, I should be able to plug in both wings in my 24'x24' shop....

But right now......it is time to take off a few days and go to Sun-N-Fun!

Forward to Finish Kit, page six

Back to Finish Kit, page four

Back to RV6 Home Page

Please submit all questions and comments to sbuc@hiwaay.net

|