Flap Construction Log

![]()

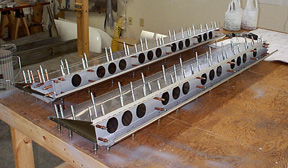

2/7/98; 6.5 hrs; drilled lightening holes in both flap braces and flap spars; fabricated both sets of flap actuator horns; deburred and scotchbrited all.

The 2" ScotchBrite wheel in the diegrinder makes quick work of deburring edges.

Here is how the 2" ScotchBrite wheel looks after several hours of deburring edges and holes.

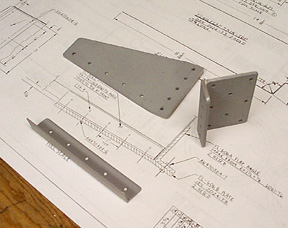

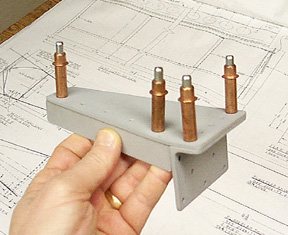

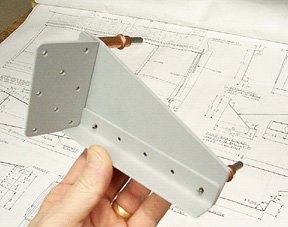

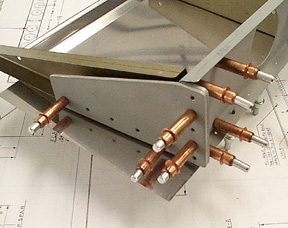

Here are the 606 A, B, and C parts. These are fabricated from angle and plate stock.

These are for the left flap. Build two of each, but remember one set is to be a mirror of this set!

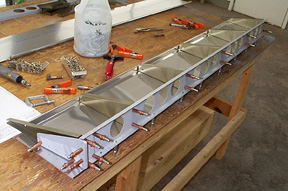

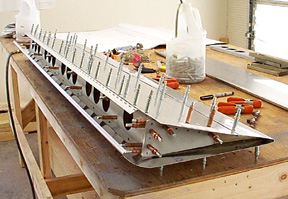

2/12/98; 2.5 hrs; assembled both flaps and drilled skins to skeletons; flaps ready for disassembly, deburring, and dimpling in preparation for riveting.

Two flaps ready for deburring and dimpling.

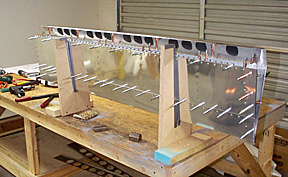

2/12/98; 2.5 hrs; disassembled left flap, deburred, dimpled, countersunk as necessary, and began riveting; built and installed V-frame for holding flaps during riveting operations.

Right flap in V-frame. Don't try riveting the flaps without the cradle!

Cradle is made from tail surface jigs; Just recut the "V" to fit the flap cross-section.

Ouch!! I never could figure out a way to get my hand in the flap and not have the fingers take a beating from the bucking bar...

2/13/98; 5.5 hrs; completed assembly and riveting of both flaps.

Flaps now complete.

Total time flaps: 17.0 hrs.

![]()