Sam Buchanan's RV6 To the Airport!

|

|

|||

Page One

Test flying begins... 9/7/99; N399SB now has 4.6 hrs on the clock. The grin is still solidly in place; This RV-6 is shaping up to be a really nice airplane! Most of the hassles so far have been due to a very leaky remote oil filter adapter. I installed a Moroso automotive racing mount on the firewall, and it has been intent on bringing me to my knees in frustration. Even after redoing every fitting associated with the mount and its hoses, oil continued to ooze to the extent that a fifteen minute flight would have oil on the belly of the airplane. I still don't know precisely where the oil is coming from, but for the time being it is a moot point. A couple of days ago I landed after yet another unsuccessful attempt to stem the tide (with the associated cowl removal/installation and cleanup) and decided that the adapter had pushed me too far. So the entire filter apparatus was yanked, the original screen reinstalled, and I am a happy camper. I am willing to change oil twice as often if the engine stays dry. Actually, I still want to determine the origin of the leaks, but at this point I am much more interested in flying than messing with leaks! High CHT has been a concern, but.........man....it is hot in North Alabama right now! This evening I flew for an hour, and the temp of the air flowing through the NACA vents into the cabin was 101 degrees at low altitudes. I only have CHT on number three, and after an evening spent browsing the RV-List archives, I have decided that it is common for #3 to be the hottest cylinder most of the time. I fabricated a baffle that covers about half of the #1 cylinder with the hopes of helping the airflow to the rear cylinder and also blocked the two-inch opening above the #3 cylinder that feeds the cabin heat muff. The intake on the right side of the cowl is much more restrictive than the left.

I also opened up the exit on the bottom of the cowl a few square inches, and the highest temp that I have seen is 425 on #3. This is still a little higher than I want, but I suspect that once the ambient air temp returns to reasonable levels, we will be ok. By the way, the oil temps are fine, running in the 180-205 range.

I am in the process of tweaking the Navaid wing leveler/auto pilot, and while the leveler mode is working pretty well, the Lowrance 100 GPS and the Navaid are not yet on speaking terms. This stuff just takes time, and that is what the twenty-five hour fly-off is all about. I really like the Rocky Mountain units even though I am having to acclimate to digital readouts vs analog. The analog unit I miss the most is the vertical speed indicator. The RV can quickly gain or lose altitude in a turn, and I am having to retrain my brain to interpret the numbers and arrows on the uEncoder. The oil leak debacle has consumed most of the flying time so far, so I don't have much in the way of hard performance numbers. The heat is supposed to break this weekend, so it will be easier to get a good idea of what the plane will do without worrying about heat stress to the plane and pilot. I do know, however, that 399SB has the potential of being a really sweet aircraft.

The only rigging adjustment that is going to be necessary is the addition of a trim wedge on the rudder; The airframe appears to be very straight. Shown is a piece of model airplane balsa aileron stock taped to the rudder trailing edge. Three flights got the size of the wedge dialed in, and the wedge will be MonoKoted (If you have to ask what MonoKote is, you ain't an R/Cer....) and glued to the rudder with RTV.

The 1200 hour 150 hp engine is running nicely, and I intend to cut open the filter I removed to see if any nasties have been trapped. 9/16/99; The oil filter has been cut open and no metal was found! Oil consumption seems to be within limits, so hopefully the engine will be good for at least a couple of years or so. I intend to have the prop dynamically balanced soon since there are a couple of rough rpm ranges that I would like to have minimized. Today I spent a couple of hours working on weepy fuel sender screws. I had been noticing some fuel scent when first opening the canopy, and upon opening the bottom of the root fairings, found fuel stains around the senders. Yes, it is possible to remove the standard senders with the wings installed even though they are a very tight fit. I put more Permatex on the screws and reinstalled them. It appears the neoprene gasket may be collapsing, so this may not be the end of the story. Next step, if necessary, may be to get out the Proseal.... I have collected some preliminary performance numbers, and they are in the ballpark for a 150 hp RV-6. At low altitude (3000'), putting the little black knob full forward will result in about 180 mph TAS. This is determined by averaged GPS runs and the TAS function of the uEncoder. At 7500' and 65 degrees F, the following numbers were obtained yesterday: 75% power (23" MAP @ 2500 rpm) = 171 mph TAS These numbers may not be exact since I only made a couple of runs at each power setting. It appears that 399SB is a few mph below book speed; This is probably due to either an over-pitched prop, or more likely, slightly draggy gear leg fairings. The intersection fairings are formed from aluminum sheet, and while they look pretty good, they aren't as slick as a nice set of glass fairings. Another factor is the mid-time engine. Since a fresh E2D develops its 150 hp rating at 2700 rpm, and I never see more than 2550 rpm, I am probably flying with a 135 hp engine! However, even though it would be nice to have a 190 mph plane, at practical cruise speeds, the penalty is minimal. If I get bored this winter, a set of slick fairings and wheelpants will make a nice shop project. 9/17/99; More numbers. This morning I did some timed climbs. The climbs started at 2000' msl (3360' density altitude) and continued to 4000' msl. The climb speed was stabilized a couple of hundred feet below 2000', the watch started as we went though 2000', and the watch stopped at 4000'. Flying weight would have been in the neighborhood of 1450 lbs. The results are below: 90 mph IAS: 983 fpm I failed to note the engine rpm at each climb, but due to the speed info from yesterday, the rpm would have been far below rated power. Another climb at 80 mph was conducted without timing, and the VSI was averaging about 1000 fpm. However, the nose was pointed waaaaay up! So, it appears that a sustained climb is going to result in similar climb rates as long as the speed is between 90 and 110 mph. Of course, the angle of climb will be greater at the lower speeds. These numbers are way below Van's published climb rates, but keep in mind that the prototypes used wood props that let the engine wind up much higher than my prop allows, and my numbers were obtained considerably above sea level. It is possible to get a zoom climb at lower altitudes that will register a much higher rate of climb (1600-1800 fpm) but my numbers represent a sustained, two-minute climb at altitude, much as you would get in the real world as opposed to "hangar" flying. Total tach time is now 14.5 hours. 9/27/99; Tach time now 22.5 hrs. Today I had the prop dynamically balanced. This resulted in a dramatic reduction in the roughness I have experienced at a couple of rpm ranges.

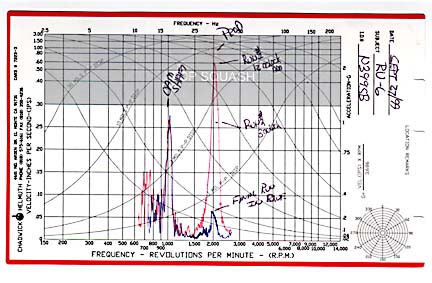

The service was provided by Jim Gaither of Dynamic Balance Service, Inc (1630 Faircrest Drive, Hueytown, AL, 205-491-6660). Jim arrived in his duelie to balance not only the prop on my plane, but also the props on an RV-6A and RV-4. Jim stated that he balanced nearly 1000 props last year, many of them RV's! He uses the Chadwick 192A system, and is an approved FAA Repair Station. The Chadwick system measures the velocity-inches/second of displacement with the engine running at 2000 rpm via a sensor attached to the crankcase.

The Chadwick plots a graph showing the displacement due to crankshaft/prop imbalance and also camshaft rotation. The system confirmed that 399SB was quite a shaker, and while the initial readout was pretty high, Jim assured me that I would definitely notice an improvement once he completed the process. The prop is new and should be in very good static balance, but I suspect that some cylinder repairs on the engine listed in the logs may have resulted in some unmatched pistons finding their way into my engine.

The above plot shows the first run in red ink (peaks at .60 ips, a rather high reading). By the way, the machine also provides a tach check (2004 actual rpm at 2000 indicated, a tribute to the accuracy of the RMI uMonitor). You can see two peaks, one at 1000 rpm and the other at 2000 rpm. The 1000 rpm spike is the camshaft running at 2X crank speed. Jim said the camshaft plot indicated that the camshaft lobes were in good shape and showed normal readings for a mid-time engine. A strobe is shot at the prop and indicates where the corrective weights should be placed on the spinner bulkhead.

Following the first run, Jim attached washers under some of the spinner screws, and the engine was run again. You can see the second run as the heavy blue line on the graph which indicates .06 ips. I knew as soon as the rpm came up that a drastic improvement was evident. The guys standing nearby said they could hear the difference in the exhaust note! After some final calculations, holes were drilled in the spinner backplate and washers were attached with AN hardware. The other RV's also required some weights even though they weren't as out of balance as my plane (matter of fact.......some folks have even gone so far as to consider the pilot of my plane as being out of balance....). The RV-6A has always been regarded as a very smooth plane, but it received a few washers as well. Ok, you are convinced of the value of dynamic balancing, but what does it cost? Having a smoother-running powerplant set me back $200 and less than an hour of my time. No doubt there will be fewer instances of material fatigue on the airframe, and 399SB has become a much more hospitable place to spend quality time.

Please submit all questions and comments to sbuc@hiwaay.net

|

Getting Ready to Build Building the Tail Building the Wings The Finish Kit

|

|