Utility Access Doors

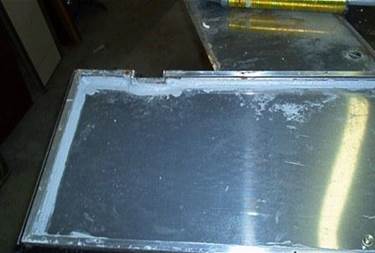

There are a few noteworthy things about the three access doors worth passing on. The exterior skin is held on the frame by plastic strips similar to what secures fixed pane windows in place. In what I found odd, Airstream did not seal the joints to keep water out. As a consequence, water got inside each door, and was soaked up by the fiberglass insulation. The insulation, in turn, held the moisture against the steel screws securing the inside door skin. The screws then rusted away from the inside out.

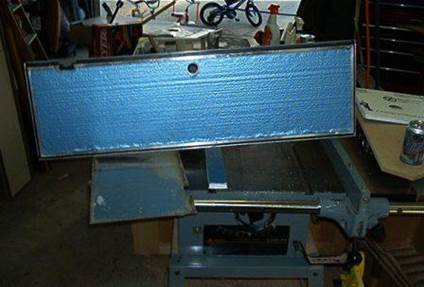

As luck would have it, I had a lot of sheet Styrofoam of the right thickness left over from the black tank insulation project. So, after Vulkeming each door’s inside leak paths, exact-fit pieces were cut on the tablesaw & installed. This was the way to go! The doors were no heavier than before, and, due to the Styrofoam’s rigidity, had a distinctly more solid feel to them.

Thanks to the Internet, I spent more time thinking about each door’s weatherstripping than was necessary. At face value, the remains of what was in place on each door looked just like the closed-cell stuff the home improvement stores sell. Concerned that it may not be that simple, attempts were made to locate the “right” stuff. Apparently, Airstream now recommends using the same gasket material on the access doors as is used on the windows & main door. I am not comfortable with that choice of material. The window gasket is a wonderful seal, but until it gets broken-in, it is really stiff. Since the One-Stop-Access is a bear to install with shore water & shore power lines attached, I used the home improvement store material. Keeping a close eye on it after several heavy rains, no leakage has been detected.

|

|

Styrofoam insulation |

|

Unsealed plastic pieces |

Vulkemed all around |