New Solardome

Number 1 son

is a great help

It’s

Springtime here in

Although

the Overlander is still winterized, one or both of the Boyz & I sleep out

there on the weekends, and the night following the hail had “Airstream” written

all over it. Although some of the videos

the Boyz choose to watch are not exactly my cup of tea, I looked forward to roughin’ it with my preschoolers in our backyard that

evening. That is until I opened the door

and found the floor soaked with water.

The hail had punched holes in both my original Solardome and rooftop

refrigerator vent cover.

Fortunately,

nothing in the trailer appeared water-damaged, and since no more storms were

predicted, we just mopped up the mess and made a night out of it anyway. I called InlandRV Monday

morning, and ordered a new solardome. The

lady I talked to there in

Although

Supply & Demand dictated that the price for the new solardome was going to

be high, I was extremely impressed at how much effort went into the thought

& construction of the new part. My

original solardome was a single, injection-molded piece of plastic which had

sagged in the middle allowing water to puddle.

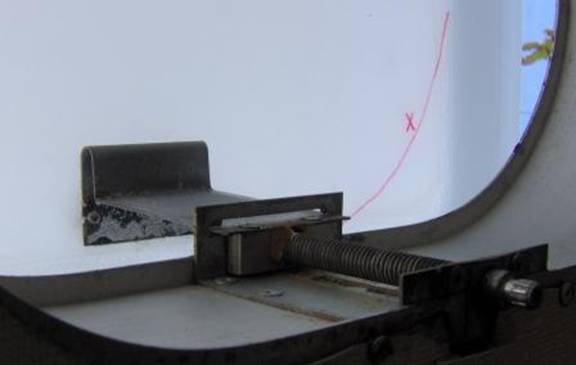

Andy’s replacement part was almost twice the weight due to what appeared

to be a separate, domed piece seamlessly welded on to an otherwise flat

cover. This new solardome looks like it

was built to stand the test of time.

While

the corners of InlandRV’s solardome are not rounded

like the original, the overall dimensions are the same. My original solardome

was attached to its two mounting brackets by six bucked rivets. Deciding to pop-rivet the new solardome on,

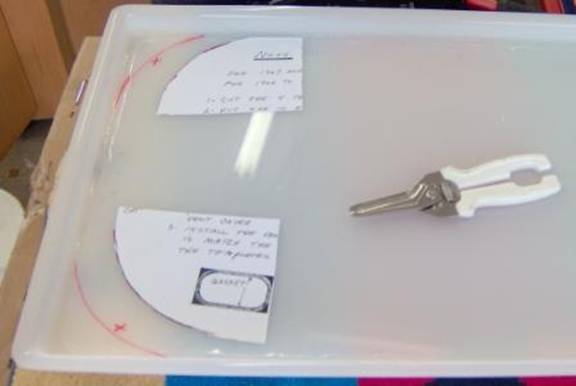

its centerline was located:

After loosely positioning the new solardome in place,

a red Sharpie was used inside the Overlander to mark the rivet holes:

Much

thought was given to whether to drill through-holes (through both layers of

plastic) or to drill only the piece of plastic closest to the mounting bracket,

and rivet from the bottom instead of the top.

Ultimately, though-holes were considered best. Backing washers were used on the rivet heads

to keep from breaking the plastic. The

rivets were coated before & after installation with clear RTV. If I had had some clear Parbond

around, I would have used that. But RTV

should be adequate

Andy

was kind enough to include a template for mounting the new [included] weatherstripping.

The lines were drawn now since it appeared to be better to install the

gasket after the new solardome was riveted in place.

I’m easy to identify on the road now – Just look for

the free advertising I’m giving Andy!