Air Conditioner Shroud

Repair

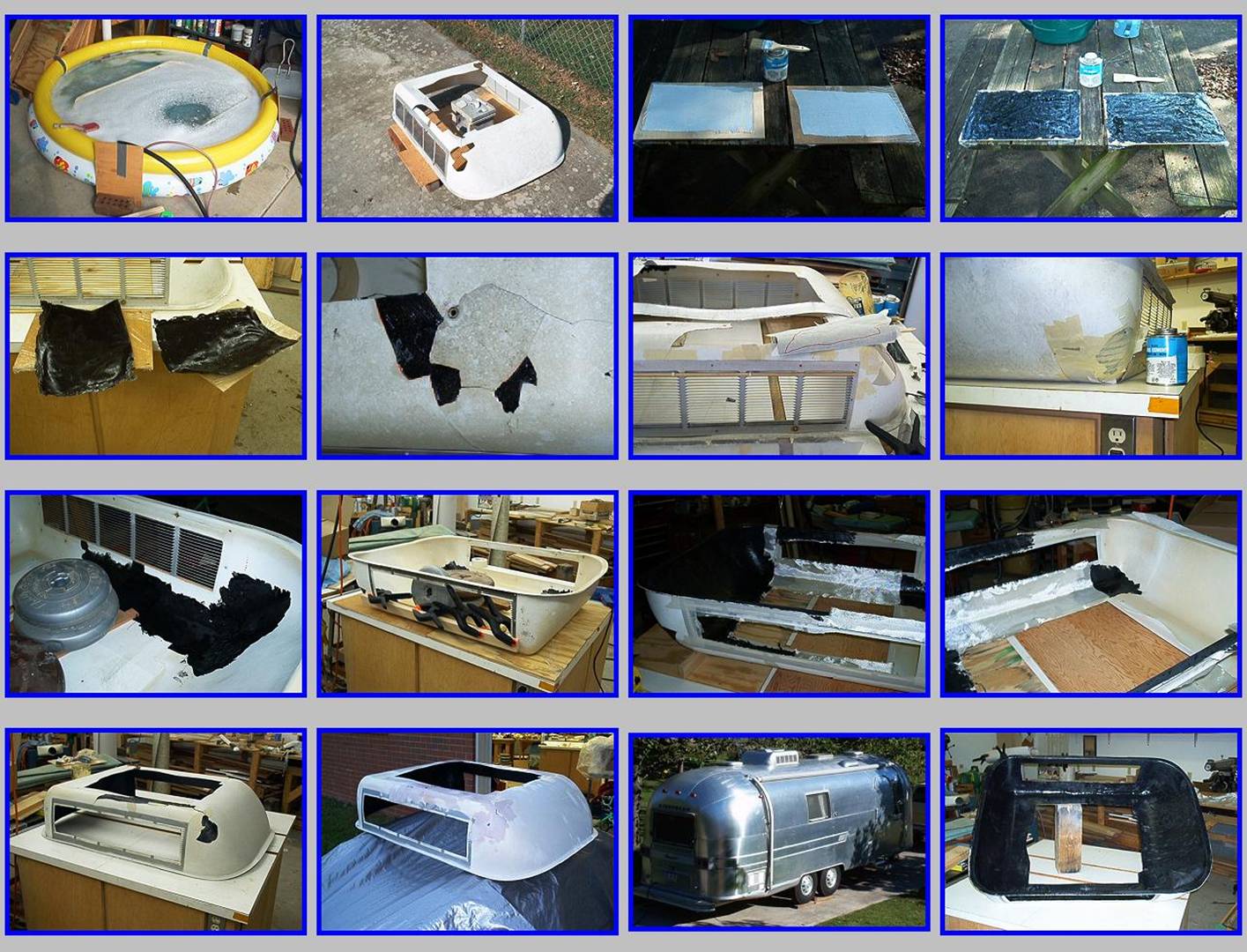

Around the time I was getting the

training wheels off of my first bicycle, the neighbor of my Overlander’s

original owner plugged the fence ROW between their two properties with pine

tree saplings. In short time, these

trees grew quite hardy, and provided a bountiful supply of pine needles, cones,

and dead branches. Unfortunately, my

Uncle’s driveway was situated directly underneath the trees, and what is now my

Overlander took more than its fair share of hits from falling branches. The air conditioner shroud, being made of ABS

plastic, responded particularly poorly.

Around the time I was getting the

training wheels off of my first bicycle, the neighbor of my Overlander’s

original owner plugged the fence ROW between their two properties with pine

tree saplings. In short time, these

trees grew quite hardy, and provided a bountiful supply of pine needles, cones,

and dead branches. Unfortunately, my

Uncle’s driveway was situated directly underneath the trees, and what is now my

Overlander took more than its fair share of hits from falling branches. The air conditioner shroud, being made of ABS

plastic, responded particularly poorly.

Although I am prone to go overboard fixing something instead of

replacing it, between the general condition of the shroud, and my general lack

of success in auto-body type repairs, I leaned very hard towards replacing this particular item. But, a new shroud was going to cost $225 plus

S&H, and since my Airstream had a list of higher priorities both time wise

& money wise, I set the shroud aside as angst for another day although I

did start researching effective repair techniques.

That day arrived seven months later when all the major repair

efforts were completed at a reasonable cost, and I finally had a clear spot on

one workbench. I set the shroud on the

bench, and stared at it while mentally reviewing the pros & cons of purchase versus patch. After considerable

thought, I pretty much decided that replacement

was in order. As a final confirmation, I

decided to walk away from it for a bit, and come back later to see if I again

had the same conclusion. So I got a cold

beer & proceeded to work some other task.

After two or three more beers, I staggered back over to that

dirty, brittle pile of antique misery sitting on my workbench, and instantly

decided that $225, although pricey, was not too

bad. So I went inside to contact the

only company in the world who sells the shroud.

Having dealt with this company before, I knew that Shipping &

Handling charges were determined when the order was filled, and the charges arrived

as a surprise with the order. Having

just paid about $22 to ship a 50 pound box big enough to ship a medium-sized

child to

$115 shipping plus $25 handling! ![]() Talk about killing a good buzz! It took me seven months just to work up to be

willing to pay for just the item. A

retirement home would find me tapping my second keg before I paid that kind of

money for the delivered item without first at least attempting a repair.

Talk about killing a good buzz! It took me seven months just to work up to be

willing to pay for just the item. A

retirement home would find me tapping my second keg before I paid that kind of

money for the delivered item without first at least attempting a repair.

After discussing the topic with others, I decided there were two

challenges to this project: Fill the

existing holes, and strengthen the entire shroud. While effecting repairs on my black water

tank, I had already researched & learned that fiberglass resin will not

stick to most plastics very well. On

another task, I had already experimented with “making” new plastic by

dissolving plastic shavings in Methyl Ethyl Ketone. While it is a sound idea, coming up with the

right formula to meet my present need was going to be time consuming. Then, while cleaning up the Shop one afternoon,

I noticed that the dried glue on a can of ABS Cement used in solvent welding

plastic plumbing together seemed to have many of the characteristics I was

looking for in the shroud’s patching material.

So, I laid some fiberglass cloth out on top of Saran Wrap, and saturated

it with ABS Cement. After the cement

dried, I was left an excellent patching material.

To remove the dirt, mold, and lichen from

the shroud, the shroud was soaked & gently scrubbed periodically in a

solution of Tide & Clorox in an old inflatable swimming pool. After rinsing & allowing to dry for a day or two, it looked considerably better.

To remove the dirt, mold, and lichen from

the shroud, the shroud was soaked & gently scrubbed periodically in a

solution of Tide & Clorox in an old inflatable swimming pool. After rinsing & allowing to dry for a day or two, it looked considerably better.

Since, when dealing with curved surfaces, every little bit of

original material helps, all the small broken pieces found under the shroud

were pieced together, and held in their original position with masking

tape. After that, all the remaining

holes were filled by cutting my homemade patching material to exact size. That part got a bit tedious since so many

curves were involved.

Working on the inside of the shroud, small squares of fiberglass

cloth were then fitted over the patched areas & soaked with ABS

Cement. This effort took place over

several days since the shroud had to be supported at various angles to keep the

cement from dripping out of the area under repair.

Once the shroud was strong enough to

support itself, the side grilles were removed, and the entire inside area was

reinforced with cement impregnated fiberglass cloth.

Top-side, most of the patched areas

turned out well. Those that did not were

simply because the curvature ended up with a flat spot. Some were filled with additional cement, but

all were wiped with Bondo to smooth them out.

Since the height of the mounted shroud makes it difficult to spot

boo-boos, I probably spent too much time Bondo-ing

& sanding, but I already told you I was prone to going overboard. ![]()

The original plan was to purchase

really good, original color paint & clearcoat to

use in my spray gun. But between the

cost of the paint, the respirator, lack of paint booth, and the fact that I

really don’t know what I’m doing with a spray gun, I opted for good spray can paint.

With the fiberglass mat strengthening the shroud, the shroud is as good as

new if not stronger. Granted although it

is probably not as strong as a shroud made completely out of fiberglass,

ultimately, the only “flying debris” issue of concern is not self-destruction

but rather the small amount of Bondo used to make the patch lines look good.

But the since the amount used was so small, I see no associated safety hazard

for anyone traveling behind me.

Although I did not weigh the shroud before or after the repair, I

was careful to not glob cement or mat on unnecessarily. Although I consider the

weight gain insignificant in the grand scheme, I have not tried to ship the

shroud anywhere…